- You have no items in your shopping cart

- Subtotal: 0.00 kr

- Home /

- Printing Jigs

Printing Jigs

Get to know jigs

Acceleration for print simplification and efficiency

What are jigs and fixtures? Jigs and fixtures are also being called templates, holders or attachments. How they serve?

1). Secure the accuracy

It holds the products on the table avoiding any misposition during the printing therefore ensuring the high accuracy.

2). Production efficiency enhancement.

For single product mass-customization production, the jig will enable the operators to load dozens of products onto the table directly while the printer is printing the other load.

No matter the type of product, printing fixtures / printing jigs are one of the main tools for direct to substrate customization process that keeps the printing accuracy.

What does this means? If you have a business that requires printing on products like golf balls, phone cases, different pens, promotional items such as lighters, key chains, and other small size items, the printing jigs and fixtures are key tools for high print quality.

These printing tools are used to hold dimensional products in fixed position during the printing process, making it an important component for LED UV inkjet printing.

Customize, design, produce and deliver on your desire

Getting professional with us and raise your demand today to us

What are the main features of artisJet printing jigs? To avoid costly production delays and defects, artisJet introduces upgraded and customized tools to fulfill any printed product requirement in terms of shape and size.

True customization even for SINGLE product

Professional design and production

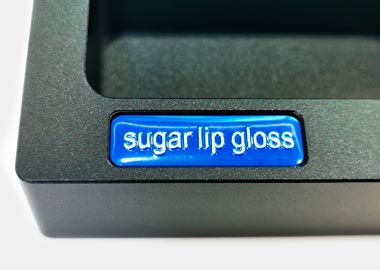

Product identification labels

Lighter material manufacture

Matte black finish

Protective individual packaging

Make you a lot more advanced

Apply to be more competitive

What are the advantages of printing jigs and fixtures? How printing jigs can improve LED UV print quality? Custom jigs, fixtures and templating with artisJet printers help you accelerate production speed to market and manage printing personalized products on demand, by holding the products in place at all stages of the printing process.

- Maintain maximum print quality and printing accuracy

- Reduce light reflection and ink mist

- Increasing productivity by templating layout

- Customized multiple sample printing in one single pass

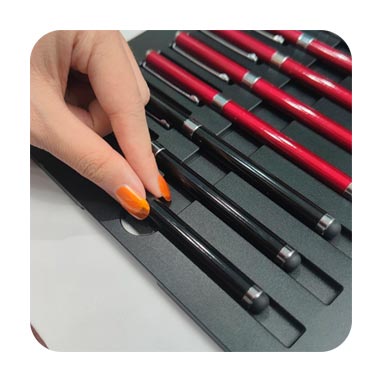

- Rapid product placement and flatbed loading time

- Quick fixture resetting with new products

- Minimizing to completely reducing rejecting printS

- Time-saving solution with reduced manual operation

Get the one that belongs to you

Standard, customized and prototyping

As a time saving solution, artisJet developed different types of printing jigs, both ready-made templates and the possibility to scan and prototype on demand printing jigs according to your business needs, available for a wide range of applications customization and also multiple items printing in one pass.

From pen printing jig, phone case printing jig for all brands (iPhone cases, Samsung cases, Huawei cases, etc.), card jig, pet tags jig, airpods jig, phone holders jig, golf products jigs, cd jig, to jigs for cosmetics such as lipstick jig, rotary jig for bottle printing and for very small cylindrical objects, jig for sunglasses, T-shirt jig, and anything else you might need to print and requires a printing fixture.

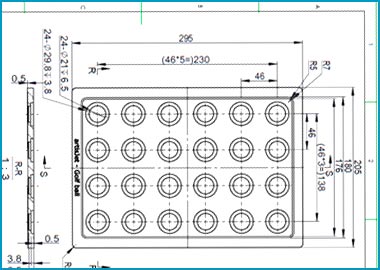

artisJet produces printing jigs of different sizes, depending on the product needs: from very small jigs to fit single products (jig for one phone case jig, single lipstick jig, one lighter jig, even jig for gold bracelet rotary printing, etc.) to A4 jigs, or B3 and B2 size jigs to fit the different printers’ flatbeds sizes. Take for example the jigs for pen printing: depending on the size of the pens, an A4 size jig has 12 slots available for pen printing, but here’s a hint: you can use two A4 jigs to fit a larger flatbed, and print 24 pens in one pass. Larger pen jigs for B2 size flatbeds can print 60 pens in one pass.

A B3 custom made jig for golf markers allows printing 77 golf markers in one shot. The smaller the item, more slots are available on the printing jig, with endless possibilities.

We will always find solutions to ease the printing workflow for different range of products. What jigs do you need?

How it works?

A hassle-free solution for software, hardware and workflow

What’s more?

Cylindrical printing with artisJet ROT 360 degrees solution

This accommodates printing on smallest cylindrical products of 1.5 cm (0.59 inches) and up to 22.5 cm (8.85 inches) diameter!